Chiller

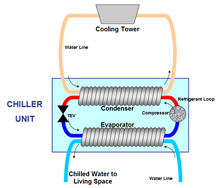

A chiller is a machine that removes heat from a liquid through an vapor compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be moved through a heat exchanger to cool equipment. Refrigeration makes waste heat as a byproduct that must be removed from it or for greater efficiency it can be recovered for heating purposes.[1] Vapor compression chillers may use any of a number of different types of compressors.The most used today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water-cooled. The chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers need a heat source to work.[2][3]

Chilled water is used to cool and dehumidify air. This is used in large commercial, industrial, and institutional buildings. For example, schools, hospitals, and factories. Water-cooled chillers can be liquid-cooled (through cooling towers), air-cooled, or evaporatively cooled. Water or liquid-cooled systems can be more efficient and have environmental impact advantages over air-cooled systems.[4]

Use in air conditioning

changeIn air conditioning systems, chilled coolant, normally chilled water mixed with ethylene glycol, from a chiller in an air conditioning or cooling plant is distributed to heat exchangers, or coils, in air handlers or other types of devices which cool the air in that area. The water is then brought back to the chiller to be cooled again. These cooling coils transfer sensible heat and latent heat from the air to the chilled water. This cools and usually dehumidifies the air. A chiller for air conditioning applications is rated between 50 kW (170 thousand BTU/h) and 7 MW (24 million BTU/h), and at least two manufacturers (York international and LG) can produce chillers capable of up to 21 MW (72 million BTU/h) cooling.[5][6] Chilled water temperatures (leaving from the chiller) usually range from 1 to 7 °C (34 to 45 °F), depending upon application requirements.[7] Chillers will get water at 12°C (entering temperature), and cool it to 7°C (leaving temperature).

When the chillers for air conditioning systems are in need of repair or replacement emergency chillers may be used to supply chilled water. Rental chillers are mounted on a trailer so that they can be quickly brought to the site. Large chilled water hoses are used to connect rental chillers and air conditioning systems.[8]

References

change- ↑ "Academia.edu - Share research". Academia.edu. Retrieved 24 January 2022.

- ↑ "Types of Chillers - A Thomas Buying Guide". Thomasnet.com. Archived from the original on 2023-05-28. Retrieved 2023-05-28.

- ↑ Evans, Paul (September 26, 2017). "Absorption Chiller, How it works". Thengineeringmindset.com.

- ↑ III, Herbert W. Stanford (2016-04-19). HVAC Water Chillers and Cooling Towers: Fundamentals, Application, and Operation, Second Edition. CRC Press. p. xvii. ISBN 9781439862117.

- ↑ "YD Dual Centrifugal Chiller". York.com.

- ↑ "Centrifugal Chiller | HVAC | Business". Lg.com.

- ↑ American Society of Heating, Refrigerating and Air-Conditioning Engineers "Handbook". Archived from the original on 2008-05-17. Retrieved 2008-05-21.

- ↑ Request for Proposal #946 - Emergency Chillers Rentals (PDF). Montclair State University. Retrieved 23 July 2015.